Royalton Music Center Creates Masks for Musicians

NAMM Member and Top 100 Dealer Royalton Music Center (RMC) has launched a line of masks that not only help protect against the spread of COVID-19 but allow for musicians to continue making music. Designed to enable musicians to return to their craft safely, the masks are being deployed not only with Royalton Music's customer base but also in music stores and schools across the country.

The family-owned Royalton Music Center has been a staple in its Ohio community for over the last 56 years. Offering services and products from full line band and orchestra instruments, guitars, amps, keyboards, percussion, sheet music, accessories, and certified repair, the retailer is a one-stop-shop for all of its customers’ musical needs. RMC also provides instruction to over 800 students each week, offers music therapy for individuals with special needs, and presents a Kindermusik class for infants and toddlers, all while being named one of NAMM’s Top 100 Dealers for the past nine years.

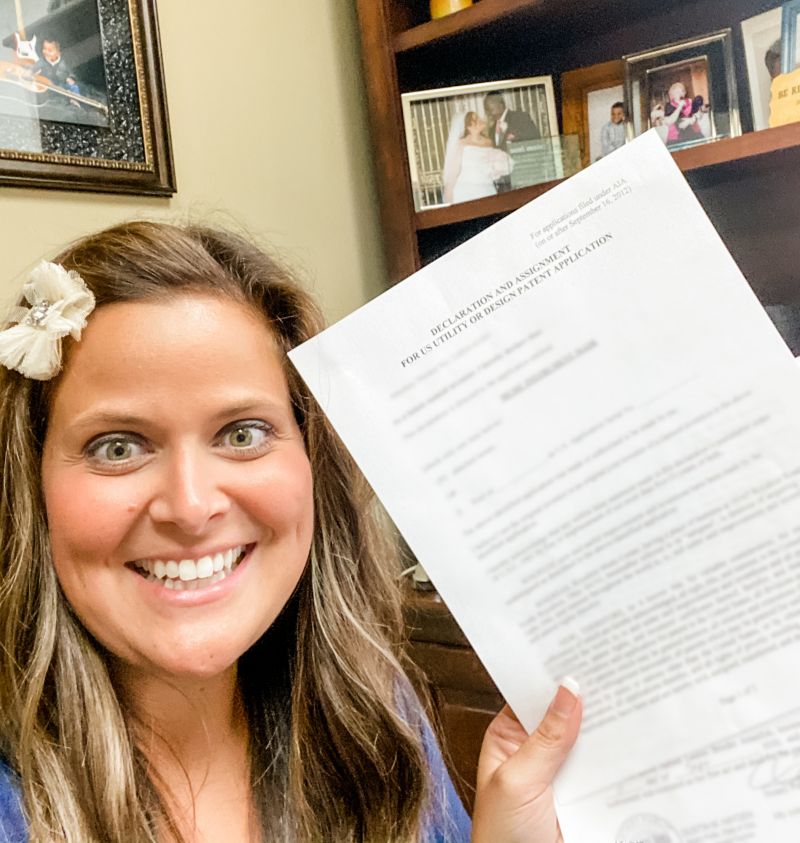

We recently spoke with Lauren Haas Amanfoh, the third-generation owner of RMC, to discuss the road to production and success of these revolutionary masks.

Why did RMC decide to start manufacturing these types of masks?

In a study supported by NAMM, the National Federation of State High School Associations (NFHS) recently published its first round of aerosol rate findings. The guidance was to mask both musicians and instruments via a bell cover, so we reached out to dozens of music industry manufacturers looking for a product for our customers. While bell covers were either readily available or on their way to market, no one at the time was able to offer a mask solution. We then started the process to find a mask pattern that we would recommend to schools and their booster clubs. We thought schools would employ parents with sewing skills in their booster clubs to make the recommended masks. Instead, many turned to us for help in purchasing completed masks. As a result, we found a manufacturer to work with to create these critical products.

Editor’s Note: Information on the NFHS aerosol study can be found at https://www.nfhs.org/articles/unprecedented-international-coalition-led-by-performing-arts-organizations-to-commission-covid-19-study/.

Can you describe the design and manufacturing process?

Being a retail store and education center, Royalton Music Center has never manufactured or distributed anything before, making this quite a unique challenge. After some trial and error with local manufacturers already producing similar COVID-19 textile products, I found a manufacturer that could meet the needs of a mask fit for musicians. After going over what did and did not work in previous prototypes, our manufacturer had a sample made within an hour, and I knew we were onto something.

The first design came to me while I was folding my son's laundry and resembled boy’s underwear. The next day I came into work and proclaimed, 'We need to figure out how to put underpants on the musicians' faces!' Ultimately (and perhaps luckily), this style of mask didn't work. Functionally, the U-shaped opening always slipped off of one ear, couldn’t accommodate a trombone or large mouthpiece, and didn't possess the right angle for a clarinet mouthpiece to fit in. We then explored materials, flaps, and ways to "close" the mask. After a series of brainstorming and samples, we ended up with our current design, which has been working exceptionally well.

How well do these masks comply with official guidelines from the experts?

We continue to follow any updates from the NFHS study, among other industry standards. Our mask is four-ply, while most on the market are only two-ply. Our stretch material only stretches one direction, avoiding "holes" in the fabric, which can allow aerosols or air to seep out. The Flute Mask is especially interesting as the material is thicker and much different from the Player's Mask. It maintains its puffed-out shape to allow air to blow across the lip plate, which is the key to producing the flute's sound. The opening in the Flute Mask is only on one side to contain as much aerosol as possible, is concealed within a pleat, and the single opening is reinforced, creating a durable mask that will last and can be laundered.

Have you received any feedback from mask users?

We have been pleasantly surprised by the response, making all of the hard work very rewarding. Judging from the dozens of repeat customers and businesses, there are thousands of satisfied musicians out there using our products. Much of the positive feedback highlights the superior quality, along with the quick availability - as the masks are Made in the USA. From initial concept to Patent-Pending and everything in between, this has been a wonderful experience and opportunity - to help musicians return to playing as soon as possible.

For more information from Royalton Music Center, please visit https://royaltonmusic.com/default.aspx.